Key Highlights

- Standard li ion battery performance degrades rapidly outside the 15°C to 35°C range, requiring robust thermal management.

- Li-ion batteries are facing the risk of thermal runaway, which necessitates integrated Protection Circuit Modules (PCM) and high-quality Battery Management Systems (BMS).

- Li ion rechargeable batteries are classified as Class 9 Dangerous Goods. Thus, they must pass UN38.3 testing for international transit.

- Chemical degradation occurs regardless of use, typically limiting standard li ion cells to 300–1,000 full charge/discharge cycles.

- Global markets (EU, US) require specialized certifications, such as IEC 62133 and CE, to ensure workplace and consumer safety.

Introduction

Li ion battery is undoubtedly the most popular and one of the most commonly used batteries in the 21st century. While lithium-ion (Li-ion) batteries offer numerous advantages, they also have some disadvantages. Understanding the inherent disadvantages of this technology is not about avoiding it, but about mastering its constraints through professional engineering and strategic sourcing.

Li-ion Battery Disadvantages

1. Thermal Runaway

The top disadvantage of rechargeable li ion battery is thermal runaway. Unlike NiMH or Lead Acid, lithium-based chemistries use flammable liquid electrolytes. If a cell is punctured (mechanical abuse), overcharged (electrical abuse), or exposed to high heat (thermal abuse), it can enter a self-heating cycle that leads to fire or explosion.

-

2. Temperature Sensitivity

In cold climates (below 0°C), the internal resistance of li on rechargeable batteries increases, causing a sharp drop in deliverable capacity. Conversely, operation in environments above 60°C accelerates the degradation of the Solid Electrolyte Interphase (SEI) layer, permanently shortening the battery’s lifespan.

-

3. Shipping Regulations

Under current IATA and IMDG regulations, li ion battery are "Class 9 Dangerous Goods." They require UN-certified packaging, specific "Cargo Aircraft Only" labeling, and a mandatory State of Charge (SoC) of 30% or less for air freight.

-

4. Limited availability of raw materials

The production of Li-ion batteries requires specific raw materials, such as lithium and cobalt. The availability and sourcing of these materials can be subject to geopolitical factors, supply chain issues, and ethical concerns. This can affect the cost and sustainability of Li-ion batteries.

-

PKCell’s Solutions for the disadvantages:

- Our custom li ion cells are paired with advanced BMS technology. The BMS monitors voltage and temperature in real-time, preventing thermal runaway.

- Our R&D team has developed proprietary electrolyte formulations incorporating phosphate and sulfite ester additives. This creates a more resilient SEI film that is resistant to mechanical stress and high temperatures.

- We can offer full UN38.3, IEC62133, and CE certifications and handle the complex documentation required for sea and air transport, ensuring customers receive their orders in time.

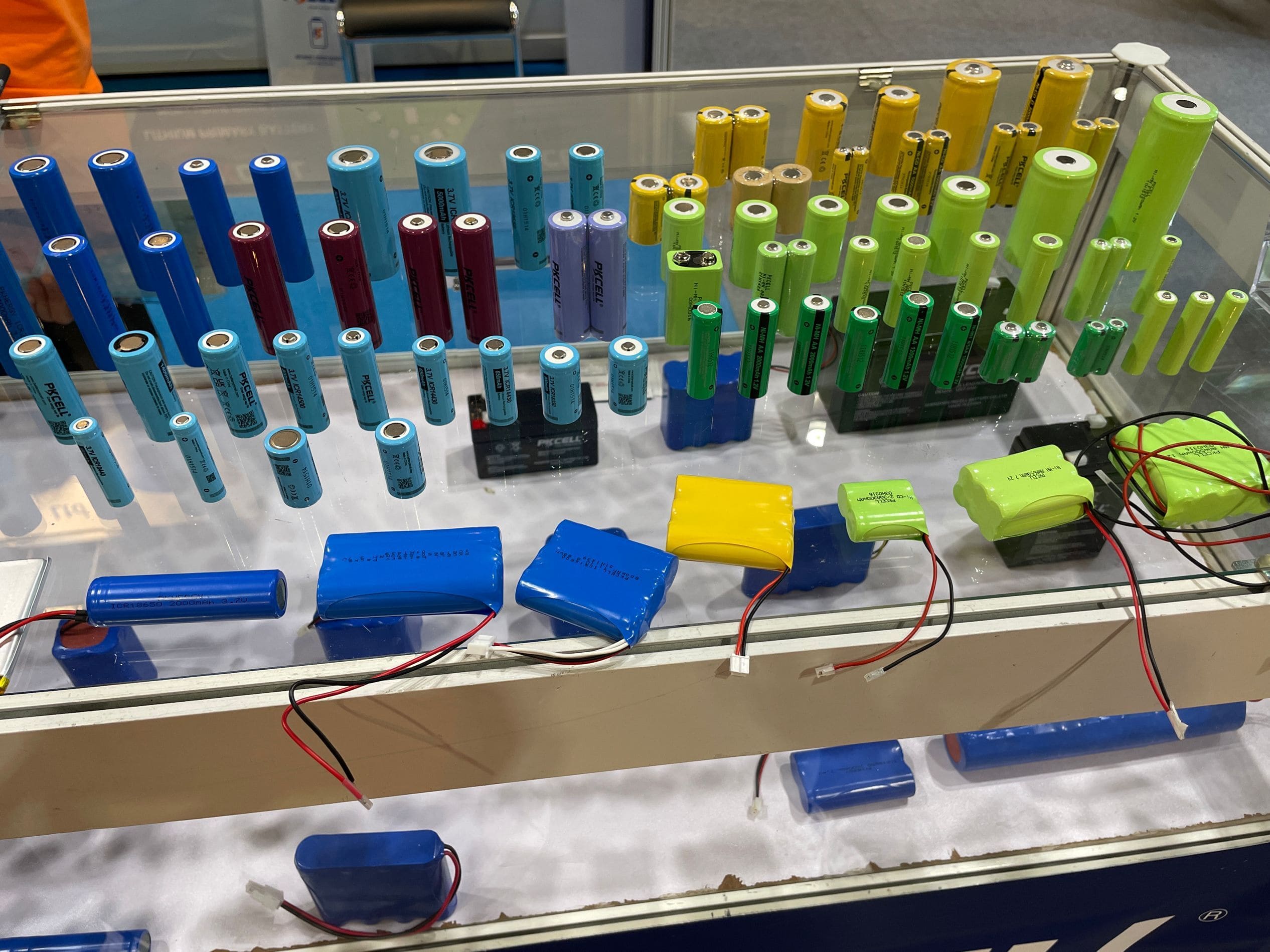

Quote for Bulk PKCell Li-ion Battery

-

4. Comparison: Li-ion vs. Alternative Chemistries

While Li-ion offers excellent energy density, other chemistries may be better suited to specific industrial needs where safety or cost is the priority.

| Feature | Li-ion (NMC/LCO) | LiFePO4 (LFP) | NiMH |

| Energy Density | High (150-250 Wh/kg) | Medium (90-160 Wh/kg) | Low (60-120 Wh/kg) |

| Cycle Life | 300 - 1,000 | 2,000 - 6,000+ | 500 - 1,000 |

| Safety | Requires BMS/PCM | Inherently Stable | Very Safe |

| Cost | Medium | Lower (Long-term) | Low (Upfront) |

| Best For | Laptops, Smart Devices | Solar, EVs, AGVs | Power Tools, Toys |

-

Why Choose PKCELL?

PKCELL is a leading Chinese B2B battery manufacturer. We have over 20 years of expertise. Operating from a 3,000-square-meter facility with 500+ professionals, we produce up to 500,000 pieces monthly. Our "One-to-One" service model ensures that every industrial client receives a custom-tailored battery solution that balances performance, safety, and regulatory compliance.

Relevant FAQs

Q: Why are li-ion batteries more expensive than lead-acid?

A: The high cost is driven by expensive raw materials (lithium, cobalt) and the complex manufacturing environment required to ensure safety and high energy density.

Q: Can a li-ion battery be used in extreme cold?

A: Yes, but the battery will have a capacity drop. For applications in sub-zero temperatures, we recommend specialized cells.

Q: Do all li-ion cells require a BMS?

A: For B2B and industrial applications, yes. A BMS is critical to prevent overcharging and deep discharge, which are the primary causes of battery failure and safety incidents.

Post time: Jul-07-2023