Why the 18650 Battery is an Industry Standard

The 18650 battery, named for its 18 mm diameter and 65 mm length, has been around for decades. Yet it remains one of the most widely used cylindrical lithium-ion cells in the world. Its popularity is not an accident.

For engineers, the 18650 strikes a rare balance: high energy density, strong continuous discharge performance, and robust safety features — all in a standardized format which is globally available. That is why it is easily found in a wide range of applications worldwide.

Standardized Form Factor and Global Supply

The 18×65 mm specification is recognized by virtually every major battery manufacturer, from Panasonic and LG Chem to Samsung SDI and PKCELL. This standardization ensures:

- Cross-compatibility between brands for OEM design flexibility.

- Stable sourcing from multiple suppliers, reducing procurement risk.

- Ease of scaling production without redesigning battery compartments.

For global manufacturers, this consistency eliminates the headaches of regional size variations.

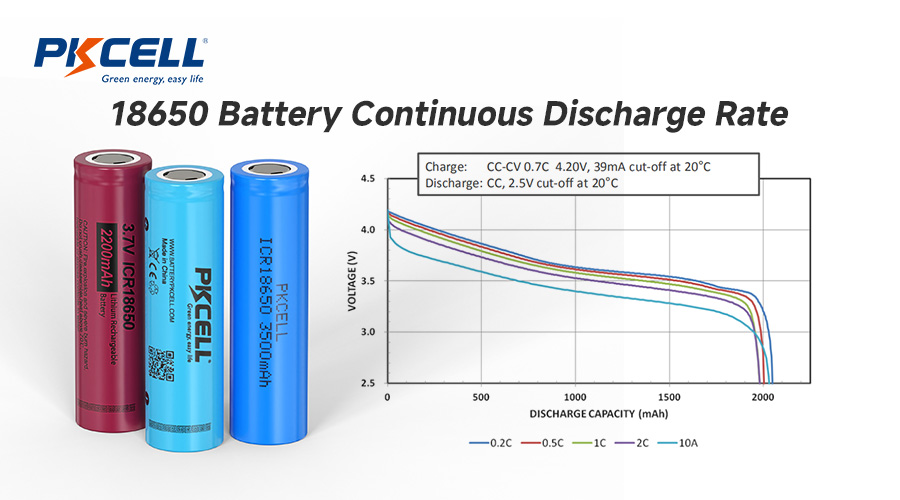

Unmatched Energy Density and Power Output

A typical 18650 cell offers 2,500–3,500 mAh capacity with energy densities of 250+ Wh/kg. High-drain variants can handle 20–30A continuous discharge, making them ideal for demanding tools, mobility devices, and tactical equipment. For B2B customers, this means fewer cells for the same performance, reducing pack weight, cost, and complexity.

Proven Reliability and Safety

Lithium-ion technology has matured significantly. Today’s 18650s incorporate advanced separators to prevent internal short circuits. They also have thermal cutoff features to manage overheating and overcharge protection in integrated pack designs to ensure people’s safety when using these batteries. Decades of production data make the 18650 one of the most predictable and reliable cells in the market.

Quote for PKCell 18650 Battery

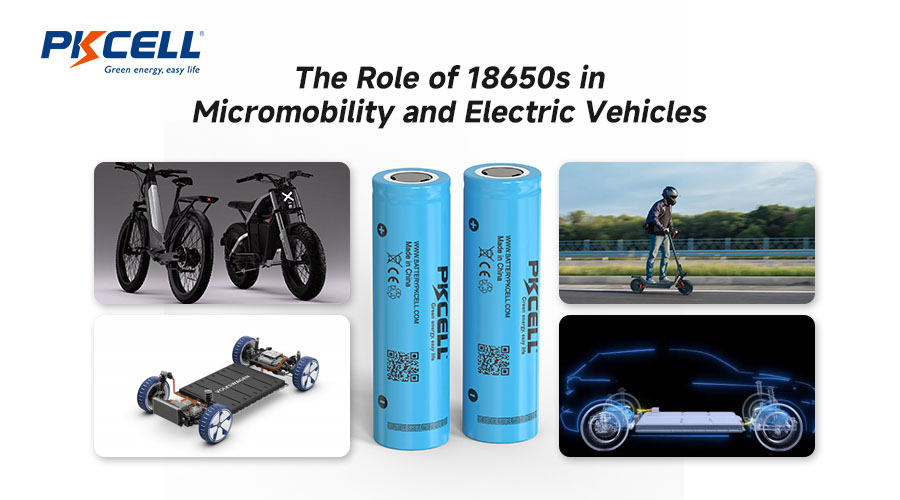

The Role of 18650s in Micromobility and Electric Vehicles

E-Bikes and Electric Scooters

E-Bikes and Electric Scooters typically require 36V–48V packs, assembled from multiple 18650 cells. A Battery Management System (BMS) is essential to balance cell voltages, protect against overcurrent, and extend pack lifespan. For OEMs, the 18650 offers flexible pack design — allowing scaling of capacity for different market segments without redesigning the core product.

The 18650′s Legacy in Early Electric Vehicles

Before pouch cells and 21700s dominated headlines, Tesla pioneered the use of 18650 cells in its Model S. Thousands of these cells were connected in parallel/series to form massive, high-energy battery packs. The takeaway? The 18650 proved that modular, cylindrical cells could power a full-size electric vehicle safely and efficiently.

Why 18650 Battery is Widely Used in Electric Vehicles

High Energy Density in a Compact Size

The 18650 battery delivers a typical voltage of 3.6–3.7V and capacities ranging from 2000mAh to over 3500mAh per cell. This high energy density allows automakers to build battery packs that support long driving ranges while keeping weight and space requirements manageable.

Mature and Cost-Effective Supply Chain

18650 cells have been mass-produced for decades for laptops and other consumer electronics. This large-scale production has created a stable, competitive supply chain. For EV manufacturers, this means lower costs, better availability, and proven quality assurance standards.

Strong Thermal Stability and Cycle Life

With proper thermal management, 18650 batteries can provide 500–1000 charge cycles while maintaining stable performance. Their safety features and durability make them well-suited for electric vehicles that demand consistent reliability in diverse operating conditions.

Modular and Scalable Design

The cylindrical form factor of 18650 batteries makes them easy to configure into larger battery packs. Engineers can arrange cells in series and parallel (e.g., 96S or 100S systems) to achieve the required voltage and capacity. This flexibility makes them a practical choice for passenger EVs, e-bikes, scooters, and even commercial fleet vehicles.

Features & Benefits of 18650 Batteries for B2B Buyers

- High Energy Density – Maximize runtime without increasing device size.

- Proven Safety Record – Millions in use worldwide with mature protection tech.

- Flexible Sourcing – Multiple manufacturers, reducing dependence on a single supplier.

- Custom Pack Configurations – Adaptable to series, parallel, or hybrid designs.

- Long Cycle Life – Lower total cost of ownership over years of use.

The Future of the 18650: A Key Player for Years to Come

While newer formats like 21700 cells are gaining attention, the 18650 will remain relevant for at least another decade. Its entrenched supply chain, design compatibility, and proven performance make it a safe, scalable choice for both established and emerging industries.

For businesses looking to balance performance, cost, and availability, the 18650 is still one of the most strategic battery investments you can make.

Why Choose PKCELL As Your B2B 18650 Battery Supplier?

PKCELL is a reliable B2B supplier with over 20 years of experience delivering high-quality 18650 lithium-ion batteries for industrial and commercial applications. Our 18650 cells offer high energy density, long cycle life, and stable performance—ideal for energy storage systems, e-bikes, power tools, and backup power solutions. We specialize in serving OEMs, distributors, and large-scale projects with consistent quality, competitive bulk pricing, and custom battery pack options. All PKCELL batteries are produced under strict quality control and certified to ISO9001, CE, and RoHS standards. Choose PKCELL for dependable 18650 battery supply that keeps your business running strong.

FAQs

Q1: How long can a quality 18650 battery last in industrial use?

A well-made 18650 can last 500–1,000 charge cycles, depending on discharge depth and operating conditions. In low-drain standby applications, shelf life can extend to 5–10 years without significant capacity loss.

Q2: Are all 18650 batteries interchangeable between brands?

Physically, yes — but electrical performance, safety features, and cycle life can vary greatly. For B2B applications, it’s crucial to source cells from reputable manufacturers with full datasheets and compliance certifications.

Q3: Can 18650 batteries be customized for my specific product?

Absolutely. OEM suppliers can configure 18650 cells into custom voltage and capacity packs, integrate BMS solutions, and add specialized terminals or casings to meet industry-specific standards.

Q4: What safety standards should I look for when sourcing 18650s?

Look for compliance with UN38.3, IEC 62133, CE, and UL certifications. These ensure the battery has passed transport, performance, and safety testing — vital for both regulatory compliance and end-user safety.

Q5: Why not switch to 21700 cells instead?

21700 cells do offer higher capacity, but they may require redesigning device housings and altering pack configurations. The 18650’s established supply and compatibility often make it more cost-effective for many B2B applications.

Post time: Aug-12-2025