For manufacturers sourcing suitable solar street light batteries, the most important factors to be considered are reliability and profitability. In a cycle of deep charging and discharging, night after night, the battery’s performance directly determines the lifespan of the street light system and its maintenance costs.

This article provides a professional B2B sourcing guide, diving deep into the mainstream battery technologies available today, and focusing on why the LiFePO4 battery has become the recognized standard in the industry.

Understanding the Performance Demands of Solar Street Lighting

The Challenge of Deep Cycling

The solar street light battery undergoes one or more charge/discharge cycles daily. If rainy weather occurs, the battery must be capable of providing several days of backup power. This necessity results in a very high “Depth of Discharge” (DoD) daily, which quickly degrades the cycle life of traditional batteries.

The TCO Imperative

B2B buyers shift their focus from the initial purchase price to the Total Cost of Ownership (TCO) nowadays. They understand that the short lifespan and frequent maintenance of traditional street light batteries result in much higher long-term operational costs (OPEX). Therefore, manufacturers started to look for better solutions.

Climate and Safety

Street lights are installed outdoors, facing challenges from extreme heat, cold, and unpredictable weather. Therefore, their batteries must endure a wide operating temperature range. The intrinsic safety of the battery is a non-negotiable component of system design, especially when installed at height and in public areas.

Comparative Technology Deep Dive: Choosing Your Core Chemistry

In the solar street light battery market, three main chemistries dominate: Lithium Iron Phosphate (LiFePO4), Lead Acid battery (Lead-Acid), and NMC/LCO Li-ion (Lithium-ion).

Lithium Iron Phosphate (LiFePO4): The Modern B2B Choice

The LiFePO4 Lithium battery has rapidly replaced conventional batteries due to its superior balance in solar applications.

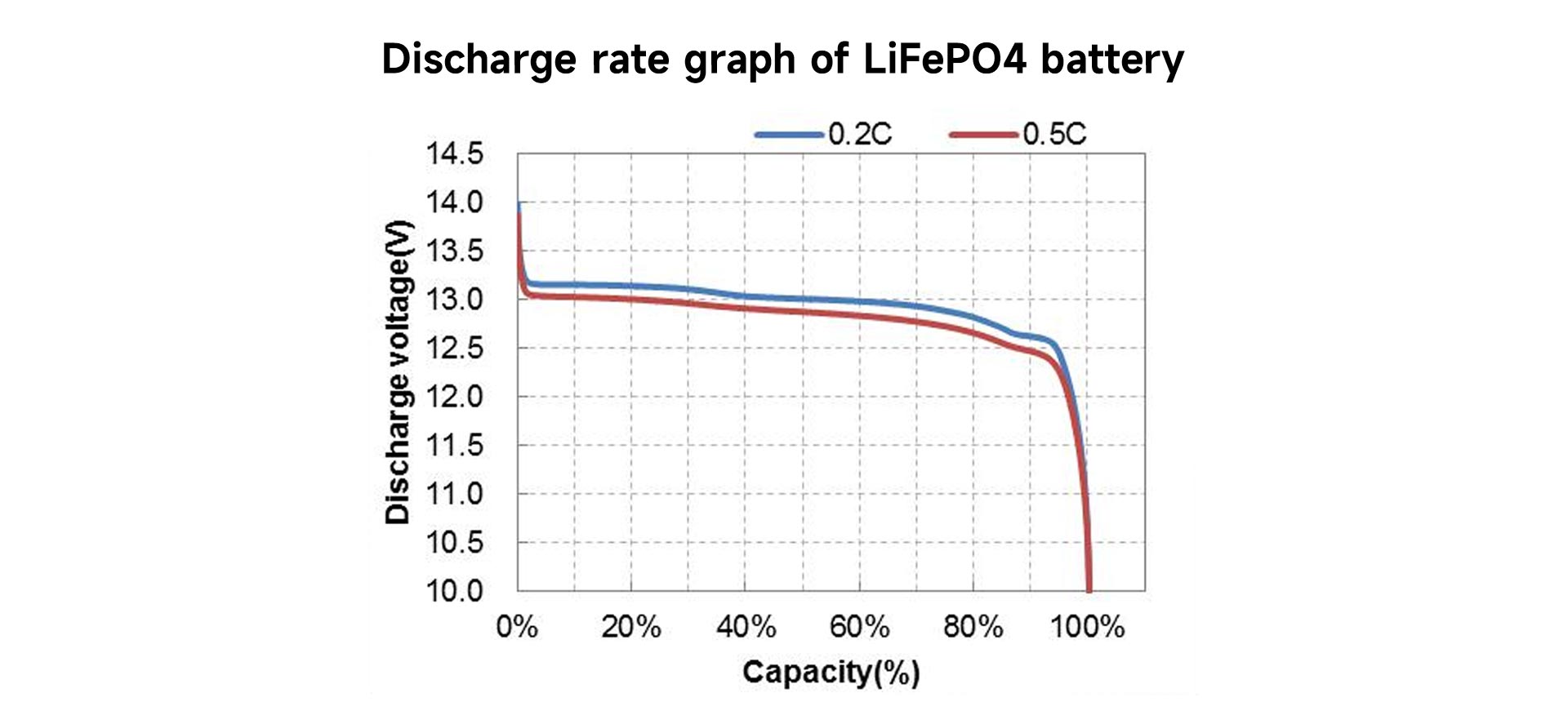

- Longevity & Efficiency: LFP batteries offer an exceptional cycle life, typically ranging from 2,000 to over 5,000 cycles (at 80% DoD), which is several times that of lead-acid. Their charge efficiency is also high, maximizing the energy utilization from the solar panel.

- Usable Energy: LFP batteries can be safely discharged to 80% or even 90% DoD. This means a 100Ah LFP battery provides far more usable energy than an equal-capacity Lead Acid battery.

- Safety Advantage: Lithium Iron Phosphate possesses inherent thermal stability, making it less prone to thermal runaway or fire even under extreme conditions. This is vital for systems integrated into the light fixture or deployed in remote areas.

Lead Acid (AGM/GEL): The Legacy Option

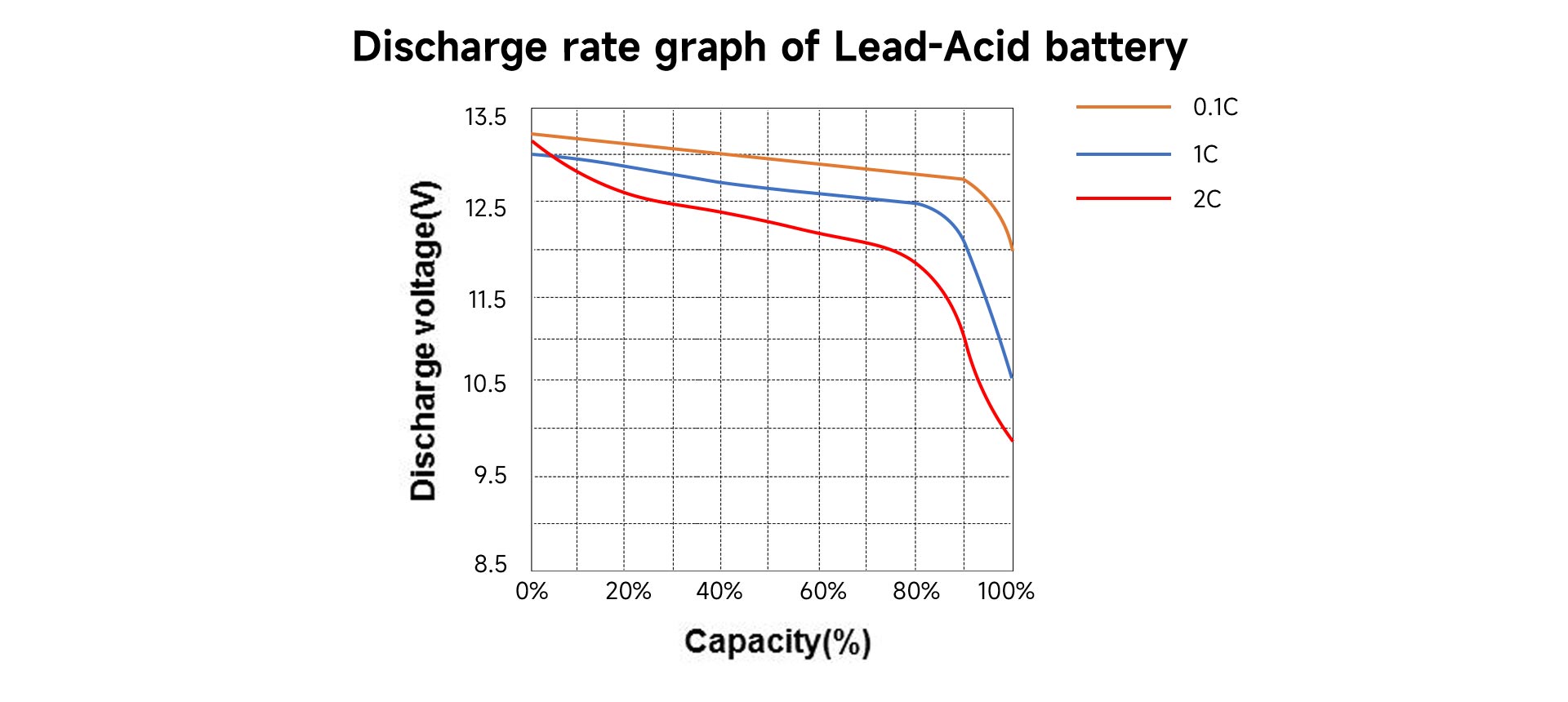

The Lead Acid battery was the mainstream choice historically, but its disadvantages are amplified in solar street light applications.

- Cost vs. Life Trade-off: While the initial price is low, the cycle life of Lead Acid battery is limited to 300–800 cycles at 50% DoD. The actual operational lifespan is only 3–5 years. This results in high maintenance and replacement costs.

- Performance Limitations: The recommended safe DoD for lead-acid batteries is only around 50% in order to preserve their battery lives. The DoD rate severly limits their usable capacity.

- Temperature Sensitivity: Lead-acid batteries degrade quickly in high temperatures and their performance drops significantly in cold weather. This characteristic compromises the street light’s reliability during winter.

Lithium-ion (NMC/LCO): The High-Density Niche

Other Li-ion chemistries (like NMC) offer higher energy density, suitable for ultra-compact street lights where space and weight are critical. However, their cost and thermal stability are generally inferior to LiFePO4, which means they require a more sophisticated Battery Management System (BMS).

Technical Comparison of Main Solar Street Light Battery Types (2025)

| Characteristic | LiFePO4 Battery | Lead Acid Battery (AGM/GEL) |

| Cycle Life (@80% DoD) | 2,000 – 5,000+ Cycles | 300 – 800 Cycles |

| Safe Depth of Discharge (DoD) | 80% – 90% | 50% – 60% |

| Expected Service Life | 6 – 10 Years | 3 – 5 Years |

| Energy Density (Wh/kg) | 90 – 160 | 30 – 50 |

| Maintenance Cost (OPEX) | Very Low (Maintenance-Free) | High (Replacement & Labor) |

| Safety / Thermal Stability | Excellent | Good |

| Total Cost of Ownership (TCO) | Lower | Higher |

Engineering the System: Technical Sizing and Management

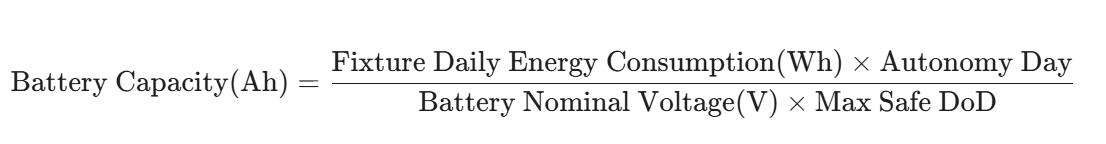

Sizing for Reliability (Autonomy Days):

Professional engineers and product designers must accurately calculate battery capacity when selecting a solar street light battery to ensure the cycle life and continuous run-time needs are met, especially during successive overcast days. The correct calculation is the foundation of system reliability:

Choosing a LiFePO4 lithium iron phosphate battery with a high usable DoD allows for the reduction of the battery’s overall size and weight while maintaining the required autonomy.

The Role of the Battery Management System (BMS):

For LiFePO4 and Li-ion batteries, a BMS is indispensable. A high-quality BMS ensures:

- Cell Balancing: Actively or passively ensuring all cells operate healthily, extending the overall cycle life.

- Temperature Protection: Preventing over-temperature discharge and, crucially, avoiding charging the LFP battery below 0°C.

- Over/Under-Voltage Protection: Ensuring battery safety and preventing system failure.

Custom Battery Pack Design

Due to the diversity in solar street light designs (integrated, split, underground), standard batteries often fail to meet all structural requirements. A professional B2B battery supplier must be capable of providing custom battery pack solutions, which include:

- Customizing the outer casing shape to fit the lamp pole or fixture space.

- Customizing cell series and parallel configurations based on system voltage (12V, 24V, 48V) and capacity.

- Integrating high-performance BMS and necessary communication interfaces.

Global Market Trends and Future Outlook (2025 Data)

Rapid Market Expansion:

The global solar street lighting market is in a phase of rapid growth. Driven by the worldwide push for sustainable infrastructure, smart cities, and rural electrification, the market is projected to expand at a robust Compound Annual Growth Rate (CAGR) of 11.5% to 18.4% through 2032.

Technological Dominance:

The market demands reliable, low-maintenance solutions. Industry analysis shows that the LiFePO4 battery is rapidly becoming the mainstream configuration for new solar street light projects. High-performance LiFePO4 technology delivers superior reliability for the solar street light battery.

Smart Infrastructure:

The future trend is the integration of solar street light battery systems with the Internet of Things (IoT) and Artificial Intelligence (AI). AI-optimized battery management systems can predict energy needs, intelligently regulate charge and discharge cycles, and enable predictive maintenance, further extending battery life and reducing operational costs.

Sourcing Your Bulk Battery Partner: The PKCELL Advantage

As a rechargeable battery manufacturer focused on the B2B market, PKCELL is dedicated to providing high-quality, bulk energy storage solutions for global manufacturers, distributors, and engineers.

PKCELL Battery, with years of manufacturing and export experience, deeply understands the core requirements of bulk purchasing clients for quality, reliability, and customization. We offer multi-chemistry solutions for your solar street light battery needs:

- LiFePO4 Solutions: Providing high-cycle, high-safety Lithium Iron Phosphate cells and custom battery pack services—your guarantee for long-term project reliability.

Quote for Bulk PKCell LiFePO4 Battery Pack

- 12V Lead Acid Battery Options: We offer reliable Lead Acid battery products for specific budget-sensitive or certain backup applications.

Quote for Bulk PKCell Lead Acid Battery

- Li-ion Battery Packs: For high energy density and compact design needs, we offer high-quality Li-ion (18650-battery-pack) solutions.

Quote for Bulk PKCell Li-ion Battery Pack

Contact us today for a bulk quote on your custom battery pack, and let PKCELL be your trusted B2B battery supplier!

Frequently Asked Questions (FAQs)

Q1: What is the ideal DoD for a LiFePO4 solar street light battery to maximize its lifespan?

A: While a LiFePO4 battery can safely discharge to 80-90% DoD, controlling the maximum daily DoD to 70% or less in real-world applications can significantly extend its cycle life.

Q2: How does the initial cost of LiFePO4 lead to a lower TCO than a Lead Acid battery?

A: The cycle life of a LiFePO4 battery is 4 to 10 times that of a Lead Acid battery, and it is maintenance-free. This drastically reduces replacement, labor, and maintenance costs. Although the initial investment is higher, its Total Cost of Ownership (TCO) is much lower over a 5-to-10-year project lifespan compared to a lead-acid battery requiring multiple replacements.

Q3: Does PKCELL offer fully assembled custom battery packs with built-in BMS?

A: Yes. PKCELL specializes in the B2B sector. We provide a one-stop custom battery pack solution, from cell selection to integrated BMS, enclosure design, and interface customization, ensuring the battery pack is perfectly integrated into your solar street light battery system.

Q4: What are the key certifications (e.g., CE, UL) I should look for when sourcing solar street light batteries?

A: Key certifications include UN38.3 (transport safety), CE (European market), UL (North American market, for cell and pack safety), and RoHS (environmental compliance). As a professional B2B battery supplier, PKCELL’s products typically hold these international certifications to meet global export needs.

Post time: Dec-04-2025