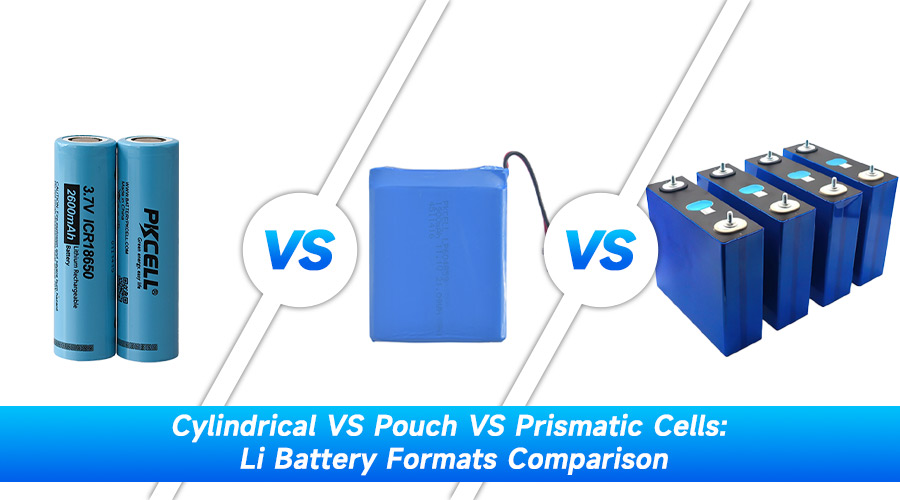

The formats of lithium batteries—whether it is a cylindrical, pouch, or prismatic cell—directly impact the device’s mechanical design, thermal management, and overall cost-efficiency. In this article, we will explain the pros and cons of each format and provide designers and engineers with some practical tips to choose suitable battery formats for product design.

Cylindrical Cells

The cylindrical lithium-ion battery is arguably the most recognizable and widely used format in history. These cells consist of a “jelly roll” of cathode, anode, and separator material tightly wound and encased in a rigid metal cylinder.

- Advantages: The primary strength of cylinder cells lies in their exceptional mechanical stability and internal pressure resistance, which significantly reduces the risk of physical deformation during high-stress operation. Because these cells are manufactured using highly automated processes, they offer the highest degree of consistency and the lowest cost per kilowatt-hour (kWh) for small to medium-sized applications. The common AA and AAA sizes are most commonly seen in daily and they are easily accessible.

- Limitations: The cylindrical format faces challenges regarding packing efficiency, as the circular cross-sections inherently create “dead space” that cannot be filled with active battery material.

- Applications: Engineers typically select this format for high-drain applications such as professional power tools, electric bicycles, and portable medical equipment, where ruggedness is a priority.

Pouch Cells: The Lightweight Energy Leader

A lithium pouch cell (often referred to as a Li-Po or lithium polymer battery) abandons the rigid metal casing in favor of a flexible, heat-sealed aluminum-plastic film. This “soft-side” approach allows the battery to be incredibly thin and adaptable.

- Advantages: The pouch battery is preferred for its highest energy density and lowest weight among the three formats, making it indispensable for weight-sensitive applications like portable electronics. This format also provides unparalleled design flexibility, as the dimensions of the cell can be customized to fit the specific footprint of a sleek consumer device.

- Limitations: One of the main drawbacks of this format is its susceptibility to swelling, as gas can build up inside the flexible casing over many charge cycles, requiring engineers to design mechanical compression into the battery compartment.

- Applications: The pouch cell is the dominant choice for modern smartphones, ultra-thin laptops, wearable health monitors, and high-performance RC models.

Prismatic Cells: Efficiency for Large-Scale Storage

The prismatic battery features a rectangular aluminum or steel casing, designed to house large electrodes that are either stacked or folded into a flat shape.

- Advantages: The primary advantage of prismatic lithium cells is their superior space utilization, as their rectangular shape allows them to be packed tightly together with almost no wasted space. Some cells are also known for their long cycle life—often exceeding 2,000 cycles when using LiFePO4 chemistry.

- Limitations: While highly efficient for large systems, the manufacturing process for prismatic lithium battery units is more complex and expensive for small-scale applications.

- Applications: This format is the gold standard for Energy Storage Systems (ESS), electric vehicle (EV) battery packs, and industrial uninterruptible power supplies (UPS).

Engineering Guide: How to Choose Your Format?

Space Constraints: If your product design prioritizes a slim profile or a non-standard shape, the pouch battery is often the only viable solution. The lithium pouch cell can be manufactured in thicknesses as small as 1mm. This allows engineers to utilize every millimeter of available space in devices

Rugged Environments: For devices that will be subjected to high vibrations, frequent drops, or extreme mechanical stress, cylinder cells are the superior choice. This structural integrity ensures that the battery remains safe and functional in industrial environments or high-impact sports equipment.

Scalability for ESS: Prismatic lithium cells allow for maximum energy density per square meter. The total number of connections and the complexity of the Battery Management System (BMS) are significantly reduced, lowering the overall system cost and improving reliability.

Technical Comparison Table

| Metric | Cylindrical Lithium Ion Battery | Lithium Pouch Cell | Prismatic Lithium Cells |

| Mechanical Strength | Highest (Rigid Can) | Low (Soft Film) | High (Metal Case) |

| Energy Density | Medium | Very High | High |

| Space Utilization | Lowest (Round shape) | High | Highest (Rectangular) |

| Cycle Life | 500 – 1,500 Cycles | 500 – 800 Cycles | 2,000 + (LiFePO4) |

| Swelling Risk | Negligible | Moderate to High | Low |

| Cost Efficiency | High (Standardized) | Medium | High (for Large Scale) |

PKCELL: Your Professional Battery Partner

PKCELL supports your procurement and engineering teams by providing a massive range of products, including our high-performance ICR/IFR cylindrical series and our LP-series pouch batteries. With certifications ISO9001, UL, CE, UN38.3, and RoHS, we ensure that your batteries meet global safety standards. Our professional engineering team will also help to customize the most suitable battery for your products. Just contact us today, and you will get competitive prices for bulk orders. You may also contact us for samples for your prototype.

Relevant FAQs

Q: Which cell format is best for long-term safety?

Cylindrical cells are traditionally considered the safest due to their ability to withstand internal pressure and their standardized safety vents.

Q: Why are pouch cells more expensive for custom projects?

The manufacturing process for a custom-sized lithium pouch cell requires specialized tooling and sealing processes. For small batches, the per-unit cost may be higher than that of standardized cylindrical cells.

Q: Can I use prismatic cells for a portable device?

It is possible, but usually not recommended unless the device is large enough to benefit from the cell’s high capacity. For small portable electronics, a pouch battery or cylindrical lithium-ion battery typically offers a better balance of weight and size.

Post time: Dec-24-2025