5 Key Highlights:

- Use fewer high-capacity cells to reduce the number of failure points in a rechargeable battery pack.

- Use cylindrical cells in a custom battery pack when size permits. They provide the best structural integrity and heat dissipation for industrial and high-vibration environments.

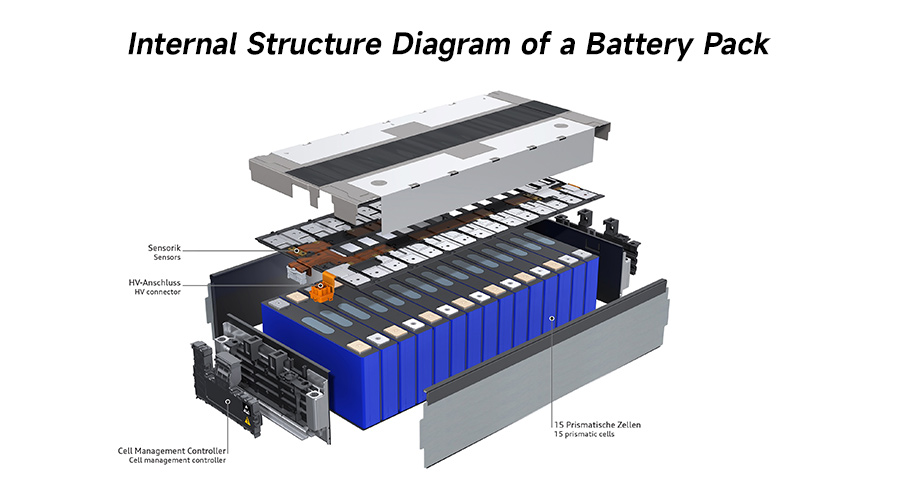

- A BMS must be physically isolated from the cells’ primary heat-generation zones to prevent sensor drift.

- Parallel configurations are limited by the weakest cell. They increase the total current of a battery pack but do not increase the individual cell’s C-rate.

- UN38.3 and IEC62133 remain the non-negotiable “gatekeepers” for global lithium battery pack distribution.

Principle 1: The “Less is More” Cell Strategy

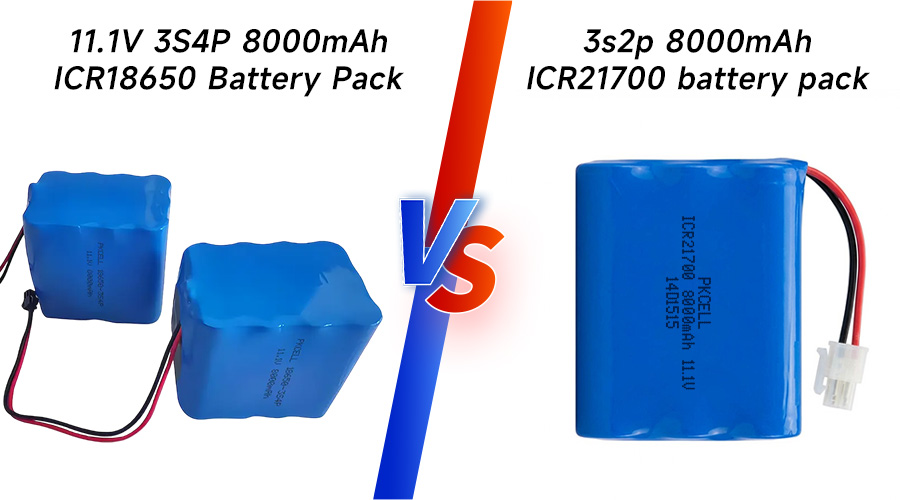

A common mistake in battery pack design is using a large number of small cells to reach a capacity target. If your product’s internal volume allows, the first principle is to use fewer cells with higher individual capacity.

By reducing the cell count, you minimize the complexity of the Battery Management System (BMS) and the number of nickel-strip welds. Fewer welds mean lower total internal resistance and fewer potential “weak links” in the circuit.

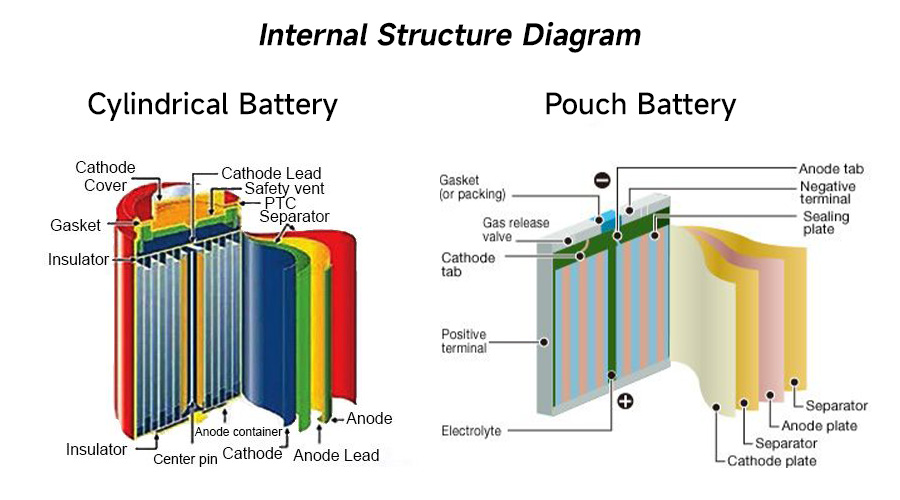

Principle 2: Why Cylindrical is King

While Li-Polymer offers “pouch” flexibility, we recommend cylindrical battery cells (18650 or 21700 in lithium-ion battery packs) if the size permits. Cylindrical cells are housed in a rigid metallic casing that naturally resists swelling and provides a consistent thermal path. This makes them safer for a vibrant working environment.

Principle 3: Proper BMS Arrangement

The BMS should not just be “added” to the pack; it must be arranged properly. This means placing the BMS away from the center of the cell cluster, where heat accumulates. Sensing wires should be routed away from high-current paths to avoid EMI (Electromagnetic Interference), which can cause the BMS to trigger false safety cut-offs.

Myth-Busting

In 2026, many engineers still fall for a major misconception regarding parallel (P) configurations:

Myth 1: Parallelizing cells inherently boosts the discharge multiplier.

The Reality: Parallel circuits increase total current, NOT the C-rate. While putting two 10A cells in parallel theoretically allows for 20A of output, it does not change the discharge rate (C-rate) capability of the individual cells.

Myth 2: Parallel will lessen capacity.

Reality: Parallelizing doesn’t inherently “destroy” capacity, but it can lessen usable capacity. A battery pack’s performance is governed by the “Barrel Effect”. If cells aren’t perfectly matched in internal resistance, the “weaker” cell hits the cut-off voltage first, forcing the BMS to shut down the entire pack while the “stronger” cells still have energy left.

Data Table: Design Configuration Comparison

|

High Reliability

|

Fewer, larger cells (21700) | Fewer failure points, easier balancing. |

|

Mechanical Durability

|

Cylindrical format | Rigid casing prevents physical damage. |

|

Smart Monitoring

|

Properly isolated BMS | Prevents heat interference with electronics. |

|

Cost Efficiency

|

Standard 18650 Parallel | Uses most widely available, cost-effective cells. |

PKCell: Your Custom Battery Pack Partner

PKCELL (Shenzhen PKCELL Battery Co., Ltd) is a leading custom battery pack manufacturer . With a 3,000㎡ facility and a dedicated engineering team, we don’t just “assemble” packs—we optimize them. Whether you need a high-voltage NiMH battery pack, Li-ion battery pack, a lipo battery pack or a high-capacity LiFePO4 system, PKCELL provides the technical expertise to ensure your design is lean, safe, and efficient.

Relevant FAQs

Does parallelizing cells reduce the lifespan?

If cells are not perfectly matched in voltage and internal resistance, parallelizing can cause “circulating currents” that effectively lessen usable capacity and lifespan.

Why does PKCELL focus on the 21700 5000mAh cell?

As a professional custom battery manufacturer, PKCell focuses on the 21700 battery because it allows engineers to follow the “fewer cells” principle, achieving high capacity with 50% fewer cells than an 18650 battery pack.

How do you ensure parallel cells are matched?

We use high-precision cell sorting machines to match cells by internal resistance (IR) and voltage within a 5mΩ tolerance before assembly.

Post time: Feb-06-2026