Key Highlights

Key Highlights

- 18650 battery packs use multiple lithium ion cells to deliver high energy density and versatility for electronics, e-bikes, power tools, and more.

- Common issues include charging failures, rapid self-discharge, overheating, and swollen cells, all of which can impact performance and safety.

- Proper troubleshooting involves visual inspection, cell voltage measurement, and checking the BMS.

- Maintenance practices like optimal charging, correct storage, and regular monitoring extend pack lifespan.

- Investing in quality cells from trusted brands such as Panasonic, Samsung, LG, and PKCELL ensures reliability.

- Knowing when to repair or replace is crucial for device safety and peak performance.

Introduction

In today’s world, 18650 battery packs are essential for powering everything from laptops to e-bikes. These battery packs, built from lithium ion cells, deliver impressive energy density and long-lasting performance. However, they aren’t immune to problems—charging issues, overheating, and poor runtime can frustrate anyone relying on these packs. Understanding common faults and effective fixes is crucial for users aiming to get the best out of their lithium ion battery packs. Let’s explore how to troubleshoot, fix, and maintain your 18650 battery packs.

What is an 18650 Battery?

An 18650 battery is a type of lithium ion battery, named for its standardized dimensions: 18mm in diameter and 65mm in length. Unlike a standard AA battery, which is smaller, the 18650 offers much higher capacity and energy storage. Each cell typically operates at a nominal voltage of 3.7V and can deliver up to several thousand milliamp-hours, making it a popular choice for high-drain devices. For any inquiries, you can always contact our telephone support team.

What sets the 18650 battery apart is its ability to maintain a stable cell voltage during both charging and discharging. The chemical reactions inside the lithium ion cell allow for efficient energy transfer and long cycle life. Because of their performance, 18650 batteries with reverse solder tabs are widely used in everything from flashlights to electric vehicles and power banks, often utilizing nickel strips in their construction. Their modular design also makes them ideal for creating custom battery packs tailored to specific voltage and capacity needs.

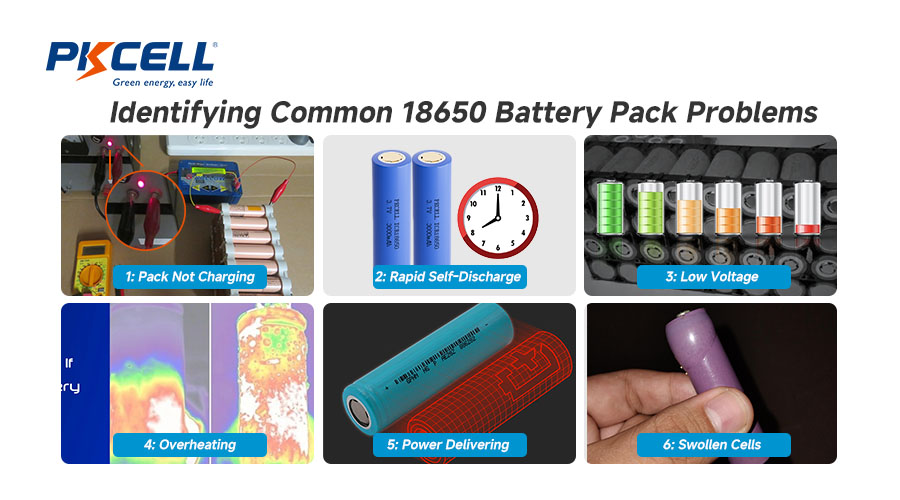

Identifying Common 18650 Battery Pack Problems

When it comes to 18650 battery packs, a range of issues can arise, affecting everything from charging to discharging cycles. You may notice your lithium ion pack won’t charge, rapidly loses charge, or even overheats during use. Other times, the Battery Management System (BMS) may trip or fail, leading to no power output at all.

Recognizing these common faults early helps prevent damage and ensures safety. Read on to discover the most frequent problems and how to spot them in your battery pack.

Problem 1: Pack Not Charging

This is one of the most frustrating problems. You plug in your device, and the battery simply won’t take a charge.

- Symptoms: Charger indicator light doesn’t change, or the battery voltage remains stagnant when connected to the charger.

- Possible Causes: Faulty charger, a tripped or damaged BMS, a completely dead cell within the pack, or loose internal connections.

Problem 2: Rapid Self-Discharge

Your battery pack charges fine, but quickly loses power even when not in use.

- Symptoms: The battery pack’s charge level drops significantly over a short period, even when idle.

- Possible Causes: Cell imbalance (where one cell drains faster than others), a parasitic drain within the device, a tiny internal short circuit in a cell, or general cell degradation.

Problem 3: Low Voltage/Poor Performance

The device powers on but operates weakly, or the battery life is drastically reduced.

- Symptoms: Device shuts off prematurely, reduced power output, or a significantly shorter runtime than usual.

- Possible Causes: Degraded cells with reduced capacity, high internal resistance preventing proper current delivery, or the BMS cutting off power due to low cell voltage.

Problem 4: Overheating During Use or Charging

Heat is a battery’s enemy. Excessive heat can indicate a serious problem.

- Symptoms: The battery pack feels unusually warm to the touch, or you might detect a distinct burning odor.

- Possible Causes: Overcurrent (drawing too much power), an internal short circuit within a cell, a faulty charger, inadequate ventilation, or even a failing cell pushing too hard.

Problem 5: Pack Not Delivering Power (No Output)

The battery is charged, but your device simply won’t turn on.

- Symptoms: The device doesn’t power up, or there’s no voltage detected at the battery pack’s output terminals.

- Possible Causes: A blown fuse within the pack or BMS, the BMS protection circuit has tripped, a broken connection, or completely dead cells preventing any power delivery.

Problem 6: Swollen Cells

This is a critical safety concern and requires immediate attention.

- Symptoms: Any visible bulging or swelling of individual cells within the pack.

- Possible Causes: Internal gas buildup due to overcharging, physical damage, or a manufacturing defect. If you see swollen cells, stop using the pack immediately and handle it with extreme caution.

Step-by-Step Troubleshooting and Fixes

Before attempting any fixes, always prioritize safety. Wear appropriate protective gear like safety glasses and gloves, and work in a well-ventilated area.

Initial Checks (Visual & Basic Diagnostics)

- Visual Inspection: Look for any obvious signs of physical damage, corrosion on terminals, or loose wires.

- Charger Check: Ensure your charger is working correctly by testing its output voltage or trying it with a known good battery.

- Overall Pack Voltage: Use a multimeter to measure the total voltage of the battery pack. Compare it to the nominal voltage.

Diagnosing and Fixing “Not Charging” Issues

- Check Charger Output: Verify the charger is providing the correct voltage and current.

- BMS Reset/Fuse: Some BMS units have a reset button or a replaceable fuse. Check your pack’s documentation.

- Individual Cell Voltages: If possible, measure the voltage of each individual cell within the pack. If one cell is significantly lower (e.g., below 2.5V for Li-ion), it might be dead or heavily discharged, preventing the pack from charging.

- Connections: Gently check and secure any loose wiring connections.

Addressing Rapid Discharge & Low Performance

- Capacity Test: If you have a battery analyzer, perform a capacity test to see if the pack is delivering its rated capacity.

- Identify High IR Cells: High internal resistance in individual cells can lead to poor performance and faster draining. Use an IR tester if available.

- Check for Parasitic Drains: If the pack drains while idle, disconnect it from the device and measure current draw to identify any background power consumption.

- Cell Balancing: If cell voltages are uneven, a proper BMS should balance them during charging. If not, a dedicated cell balancer might be needed (for advanced users only).

Managing Overheating Issues

1. Reduce Load: If the pack overheats under load, your device might be drawing too much current for the pack’s specifications.

- Improve Ventilation: Ensure the battery pack has adequate airflow, especially in enclosed spaces.

- Inspect for Internal Shorts: This is an advanced and risky step. If you suspect an internal short, it’s safer to discard the pack.

- Replace Faulty Components: If a cell or the BMS is consistently overheating, replacement is often the safest option.

Solutions for “No Power Output”

- Check Fuses: Many packs have internal fuses that can blow to protect against overcurrent.

- BMS Trip: The BMS might have tripped due to over-discharge or overcurrent. Disconnect the pack and let it rest, then try to reset the BMS (if applicable).

- Verify Connections: Ensure all positive and negative terminals, as well as balance leads, are securely connected.

- Pinpoint Dead Cells: Measuring individual cell voltages will reveal any completely dead cells that are breaking the circuit.

When to Seek Professional Help or Replace

While DIY troubleshooting can be effective, some situations warrant professional help or immediate replacement:

- Severe swelling, strong chemical odors, or smoke from the pack. These are critical safety hazards.

- Inability to diagnose or fix the problem after basic troubleshooting attempts.

- Any situation where safety concerns outweigh your comfort with DIY attempts. It’s better to be safe than sorry with lithium-ion batteries.

Maintenance Tips for Extending 18650 Battery Pack Lifespan

Proactive maintenance is key to keeping your 18650 battery packs healthy and extending their operational life.

Optimal Charging Practices

- Avoid Extreme Charging/Discharging: Don’t regularly charge to 100% or discharge to 0%. Aim for a charge cycle between 20% and 80% for maximum longevity.

- Use Appropriate Chargers: Always use a charger specifically designed for 18650 lithium-ion batteries and compatible with your pack’s voltage and chemistry.

- Avoid Trickle Charging: Don’t leave Li-ion batteries on trickle chargers for extended periods after they’re full, as this can stress the cells.

Proper Storage Conditions

- Store at Recommended Charge Level: For long-term storage, charge Li-ion 18650 packs to around 30-50% of their capacity.

- Cool, Dry Place: Store batteries in a cool, dry environment, away from direct sunlight, extreme temperatures, and flammable materials.

Cell Balancing Importance

Balanced Cells = Healthy Pack: Ensuring all cells in a pack have similar voltages prevents individual cells from being overcharged or over-discharged, which can severely degrade the pack’s overall capacity and lifespan. Use a BMS or charger with balancing features.

Regular Monitoring and Inspection

- Periodically Check Voltages: For packs without a smart BMS, periodically measure the overall pack voltage and, if possible, individual cell voltages.

- Look for Physical Signs: Regularly inspect the pack for any signs of physical damage, swelling, or leaks.

Beyond Troubleshooting: Investing in Quality 18650 Cells fro

Even with diligent troubleshooting and maintenance, a reliable 18650 battery pack starts with quality cells. Investing in high-quality cells from a reputable manufacturer significantly reduces common issues and ensures consistent, safe performance throughout your pack’s lifespan. This is where PKCELL excels. As a trusted manufacturer, PKCELL provides 18650 cells known for their reliability, durability, and robust safety features, helping prevent problems like overheating and premature degradation. Choosing PKCELL means investing in a component that enhances the long-term stability and safety of your devices. Explore PKCELL’s range to find the right fit and experience the difference quality makes.

Conclusion

In conclusion, troubleshooting 18650 battery packs involves understanding common issues and implementing effective fixes. By diagnosing problems like rapid self-discharge, overheating, or low performance, you can extend the lifespan of your batteries and ensure optimal performance. Regular maintenance practices, such as proper charging, storage conditions, and cell balancing, play a crucial role in maintaining battery health. Investing in quality 18650 cells from trusted manufacturers like PKCELL can also make a significant difference in reliability and safety. If you’re ready to enhance your battery experience, don’t hesitate to get quotes for commercial solutions that suit your needs.

Frequently Asked Questions

How can I safely dispose of or recycle old or damaged 18650 battery packs?

Proper disposal of lithium batteries is crucial for safety and the environment. Take the battery pack to a certified recycling center or hazardous waste facility. Never throw lithium ion batteries in regular trash, as they can cause fires or leaks. Check local recycling guidelines for details.

Can I fix a swollen 18650 battery?

Never attempt to repair or reuse swollen lithium battery cells. Swollen cells indicate dangerous internal failure and pose serious safety risks. Safely remove the battery pack from use and recycle it at an approved center. Protect yourself and the environment by not tampering with damaged lithium ion batteries.

How often should I check my 18650 battery packs for issues?

Inspect and monitor your lithium ion battery pack monthly or after every 20-30 charging cycles. Check cell voltage, physical condition, and charging behavior for signs of trouble. Regular inspection helps catch problems early, ensuring safe operation and extending pack lifespan.

Post time: Jul-31-2025